Why an Engineering-Led Massager Manufacturer Matters for Quality

- By Grace

- Updated on

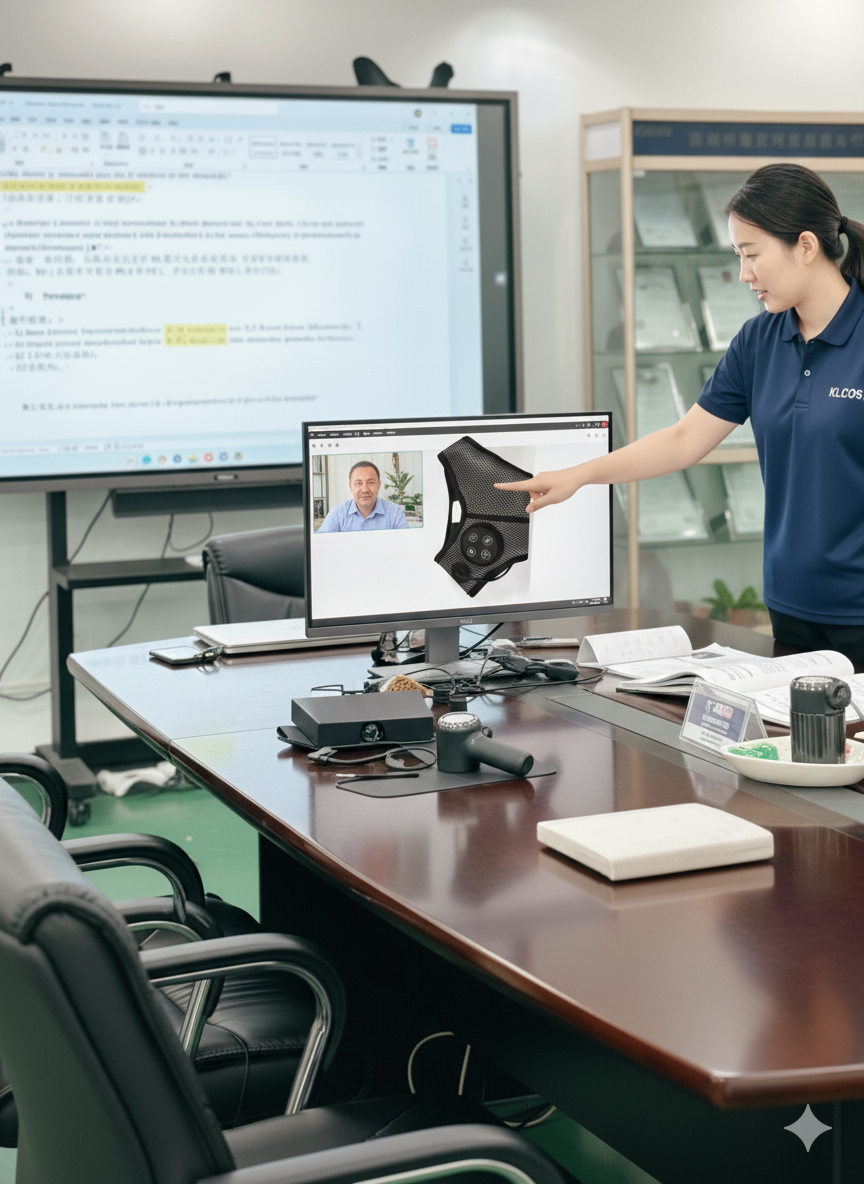

You've partnered with a factory that seemed highly capable during the sales process. But the moment a real technical issue arises, your "project manager" goes silent. They are a salesperson, not an engineer. They become a bottleneck, forwarding your urgent questions into a black hole and returning with vague, translated answers days later.

This communication gap is more than just frustrating; it's a critical business risk. It creates delays, compromises quality, and leaves you feeling powerless, trying to solve complex engineering problems from thousands of miles away without a true technical counterpart on the ground.

At KLCOSY, we’ve built our company on a fundamentally different principle: we are an engineering-led manufacturer, not just a labor-led one. Our massager factory team structure is a deliberately designed asset, created to provide our partners with direct access to technical expertise and to ensure that every project is driven by engineering discipline, not just sales promises.

What Does a 1:10 Engineer-to-Worker Ratio Really Mean for You?

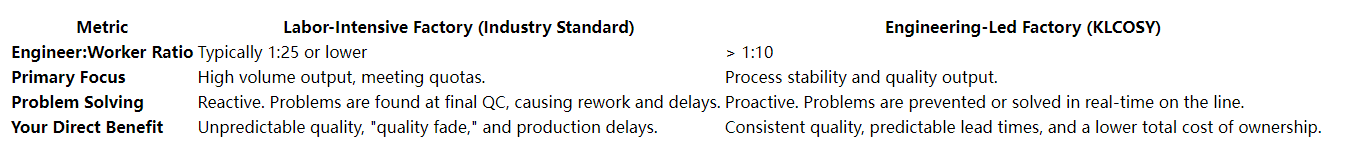

You're reviewing factory profiles, and they all boast about their large number of assembly workers. But a high headcount can often mask a lack of technical depth. A factory with hundreds of line workers but only a handful of engineers is a massive red flag.

We believe the ratio of technical staff to production staff is the single most important indicator of a factory's commitment to quality. At KLCOSY, we maintain a high ratio of over 1 engineer for every 10 production workers. The COO of a robotics company that partnered with us put it best. He said, "Your high engineer ratio proves you invest in the process, not just the labor. It means you're solving problems at the source, on the factory floor, not just inspecting them at the end."

Our team of over 100 employees includes more than 20 dedicated R&D and Quality Control specialists. An engineering-led culture means that supplier technical expertise isn't siloed in an office; it's embedded directly into the production floor. Our engineers work side-by-side with our production staff, providing real-time training, optimizing workflows, and implementing continuous improvement initiatives. When a deviation occurs on the line, it's not just a line worker who notices it; it's an entire system, overseen by engineers, that is designed to detect and correct it instantly.

Engineering-Led vs. Labor-Intensive: The Impact on Your Business

Who's Your "Project Manager"—A Salesperson or an Engineer?

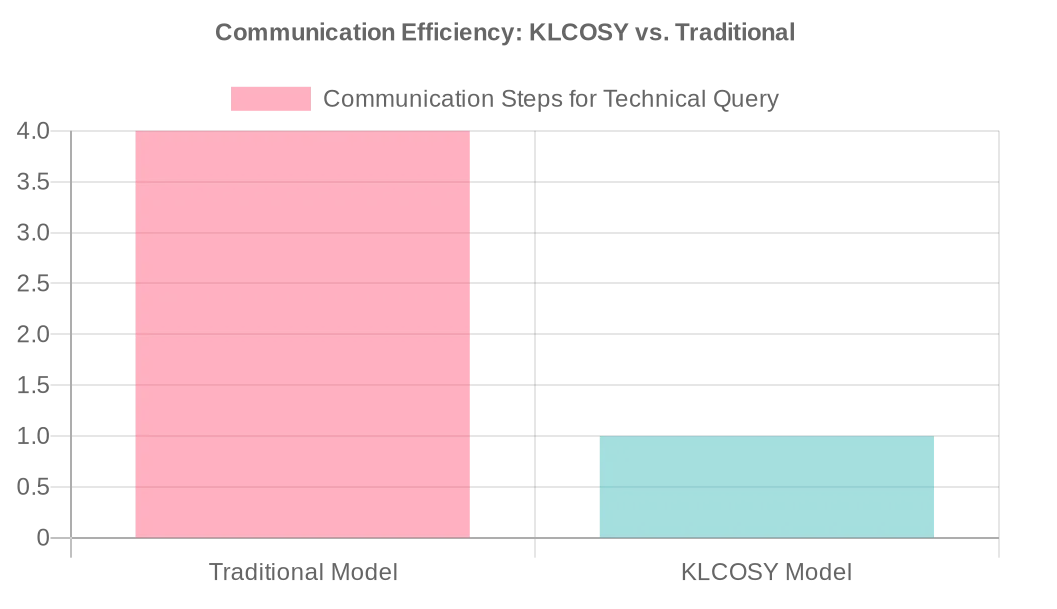

You have a critical question about the DFM report for your new product. You need to discuss draft angles and material flow with someone who understands the technical trade-offs. The last thing you need is to explain the issue to a salesperson who can only promise to "check with the factory."

That is a scenario our partners never face. At KLCOSY, your primary point of contact is a dedicated Project Engineer, not a sales-based account manager. A purchasing manager for a European electronics brand told us their previous PM couldn't even read a CAD drawing. She said our model, where the Project Manager is a qualified engineer, cut their issue resolution time by 80%. This is the critical difference in the project engineer vs account manager debate.

We believe the person managing a technical project must be a technical expert. Our Project Engineers all have a formal background in mechanical or electrical engineering and a minimum of five years of experience. They are bilingual and serve as your single, accountable point of contact, owning your project from the initial DFM analysis all the way through to mass production. They aren't a relay for information; they are a true technical counterpart. This structure transforms our private label manufacturing partnership from a simple client-vendor relationship into a collaborative engineering team.

This direct communication path doesn't just save time; it eliminates the errors and misunderstandings that are inevitable when critical technical information is passed through multiple non-technical intermediaries.

How Do You Protect My Project from the 'Brain Drain' of Staff Turnover?

You’ve spent a year working closely with a project manager at your supplier. They understand your product, your quality standards, and your history. Then, they suddenly leave the company, and all of that critical, unwritten project knowledge vanishes with them. You're forced to start from scratch with a new contact.

This "brain drain" is a huge and often hidden risk. We mitigate this with a two-pronged strategy: a culture that promotes stability and a robust system that ensures knowledge is retained by the organization, not just by an individual. The founder of a startup we've worked with for five years told me he's had the same project engineer the entire time. "That continuity," he said, "is a priceless competitive advantage."

Our staff turnover rate, particularly among our senior technical staff, is exceptionally low—consistently below 5% annually. We achieve this by investing heavily in our team's professional development. But we know that people are only one part of the equation. A truly resilient organization relies on systems. We have built a robust knowledge management system to ensure that project continuity is never at risk.

Our System for Institutional Knowledge Retention:

- Centralized Digital Documentation: Every critical document for your project—from the DFM report to every approved spec sheet—is stored in a centralized, project-specific digital folder.

- Standardized Processes: We rely on standardized, documented processes for everything from new product introduction to managing engineering changes. The process holds the knowledge.

- Cross-Functional Team Collaboration: Your Project Engineer doesn't work in a silo. They are part of a cross-functional team that includes members from R&D, Quality, and Production. Key decisions are made and documented in a collaborative environment.

The quality and reliability of your product are a direct reflection of the quality and stability of the team that builds it. Our engineering-led model, our assignment of dedicated Project Engineers, and our systematic approach to knowledge retention are all designed for one purpose: to provide the technical competence and operational predictability you need to de-risk your supply chain. When you choose a massager manufacturer, you're not just buying manufacturing services; you're investing in a partnership with a world-class technical team.