Chinese Portable Massagers Manufacturer: The Strategic Choice for ergonomic design

- By Grace

- Updated on

Struggling with uncomfortable massagers? Poor design can cause more strain. As a leading portable massagers manufacturer, we solve this problem by putting ergonomic principles at the core of our development process.

As a manufacturer, I ensure ergonomic design by focusing on human factors engineering, from anatomical studies to user testing. We create versatile massagers with an adjustable fit, intuitive controls, and skin-friendly materials for a truly comfortable and effective experience.

But what does this process look like in detail, and what specific features should you, as a buyer, look for? This commitment to comfort is not just an added feature; it is essential for a product's success. Let’s explore how we bring comfort and usability to the forefront of our designs and what it means for your business.

Key Ergonomic Features in wholesale portable massagers from China

Sourcing a massager that truly sells? Customers often abandon devices that are clunky and hard to use. Key ergonomic features are the difference between a market hit and a miss, especially when sourcing wholesale portable massagers.

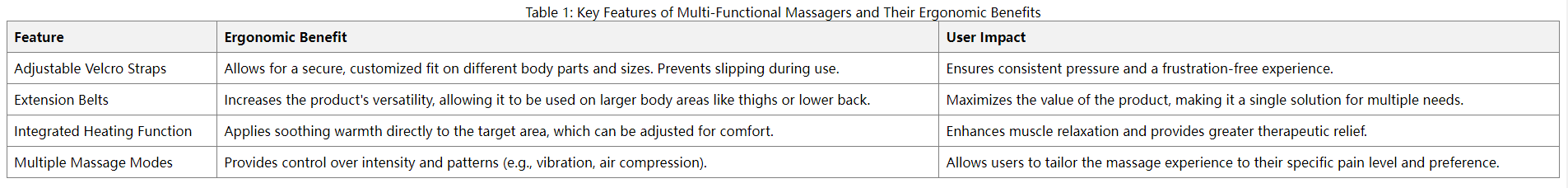

When I evaluate a massager design, I look for an adaptable fit through adjustable straps and extension belts. It must have an intuitive, easy-to-reach control panel, customizable modes like heat and compression, and be made from soft, breathable materials.

When you're sourcing multi-functional portable massagers, it's easy to get lost in specifications like motor type or battery life. However, the features that determine whether a customer loves or hates a product are often rooted in its ergonomic design. A powerful compression motor is useless if the device constantly slips off the user's knee or if the straps are scratchy and uncomfortable. It's a key reason why successful Chinese portable massagers use ergonomic design as a core philosophy, not just a bonus feature. From my years of experience developing these products, I can tell you that success hinges on a few critical ergonomic elements. These elements are not just about looks; they are about fit, function, and long-term usability. A product that conforms to the body and is simple to operate will always outperform one that ignores these fundamental principles. It creates a better user experience, which leads to positive reviews and repeat business for your brand.

Form Factor and Handling

The first thing a user notices is how a massager fits on their body. For a multi-functional device designed for arms, legs, and shoulders, this is about secure and comfortable application, not just how it feels in the hand. We focus on three key areas: adjustability, versatility, and ease of use. The core of the design lies in high-quality, adjustable straps, often using strong Velcro, that allow users to achieve a snug fit on various body parts. We also design extension belts, which are crucial for adapting a smaller arm massager for use on larger areas like the hips or thighs. The placement of the control unit is also a major ergonomic consideration. It must be positioned so the user can easily see and reach it to change settings without having to awkwardly twist or remove the device.

Adaptability and Customization

Every body is different, and so is every ache. A one-size-fits-all approach doesn't work. That’s why high-quality massagers must be adaptable. With multi-functional massagers, this adaptability comes from both their physical design and their features. The ability to use the same device on a knee, an arm, or a shoulder through well-designed straps and extensions is the primary form of customization. Beyond the fit, adjustable settings are non-negotiable. Users need to control the intensity of the air compression or vibration, and they often want a heating function with multiple temperature levels. This personalization ensures the massage is always effective and comfortable, suited to different sensitivities and therapeutic needs.

Material Science and User Interface

The materials that touch the user's skin for extended periods must be safe, comfortable, and durable. We select soft, breathable fabrics like diving material for the interior lining. These materials are skin-friendly, prevent excessive sweating, and are wear-resistant. The outer casing is just as important. A premium-feeling fabric adds to the perceived value. We also consider acoustic insulation to dampen motor noise, creating a more pleasant and relaxing user experience. Finally, the user interface—the control panel—must be intuitive. We use large, clearly labeled buttons with tactile feedback and simple LED indicators so the user can change settings without confusion, even when the device is strapped to their body.

Can a Chinese ODM Validate Your custom portable massagers with User Testing?

Worried your custom design won't feel right? A great idea on paper can easily fail when a user tries to strap it on. That is why professional user testing is the only way to be sure.

Absolutely. As an ODM, conducting user testing is a core part of my validation process. I create physical prototypes of custom portable massagers and gather direct feedback from diverse user groups to refine the design, ensuring the final product is comfortable, intuitive, and effective for your target market.

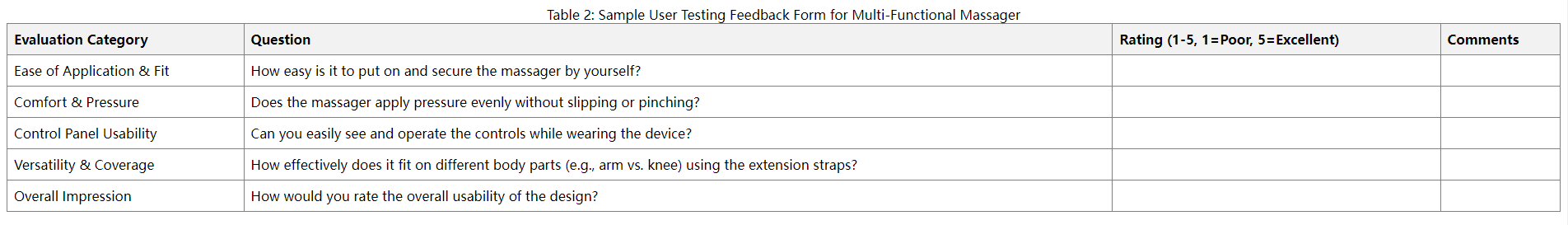

One of the biggest concerns I hear from clients like Jeff is whether a theoretical design will translate into a real-world product that people love to use. This is where the role of a true ODM partner becomes clear. We don't just take a drawing and manufacture it; we bring it to life through a rigorous process of testing and refinement. Simply relying on 3D models and simulations is not enough. You can't feel how a strap digs into the skin or how easy a control panel is to use when you can't see it. Real-world validation is essential, and it's a service we provide for all our ODM portable massagers to ensure the product we develop for your brand meets the highest standards of usability and comfort. This process de-risks your investment and significantly increases the chances of market success.

The Prototyping Stage: From Digital to Physical

Our process begins long before a user ever touches the product. It starts with detailed 2D sketches and 3D CAD (Computer-Aided Design) models. Here, our engineers and industrial designers collaborate to define the initial form. We use simulation software to analyze factors like pressure distribution from air bladders and heat consistency. But these digital models are just the first step. The most critical phase is creating physical prototypes. We use techniques like sewing, 3D printing for control housings, and assembling functional electronic components to produce complete mock-ups. These aren't just display models; they have the intended fit, materials, and full functionality. This allows our team and, most importantly, you, the client, to try the design and provide initial feedback before we move to more expensive tooling.

The User Feedback Loop

Once we have a solid prototype, we initiate the user testing loop. This is a structured process designed to gather actionable feedback. We recruit a diverse group of testers representing different ages, genders, and body types to ensure the design works for a broad audience. Each tester is asked to perform a series of tasks with the prototype, such as strapping it onto their arm, then using the extension belt to fit it onto their thigh, and operating all the controls. We observe them and then collect their feedback through structured questionnaires and interviews. We don't just ask, "Do you like it?" We ask specific questions about the comfort of the fit, ease of adjustment, and clarity of the controls.

Iterative Refinement and Validation

User testing is not a one-time event. It is an iterative cycle. We take the feedback from the first round of testing and bring it back to our design team. For example, if multiple users report that the straps are difficult to tighten by themselves, we might change the material or the design of the buckle. If they say the control unit is in an awkward spot, we will test new placements. We then create a new, revised prototype and conduct another round of testing. This loop of 'design-prototype-test-refine' continues until we have addressed all major usability issues and the feedback is overwhelmingly positive. This data-driven approach removes guesswork and ensures that the final design is validated by real users, giving your product a significant competitive advantage when it hits the market.

How Ergonomics Drives Success for Private Label Portable Massagers

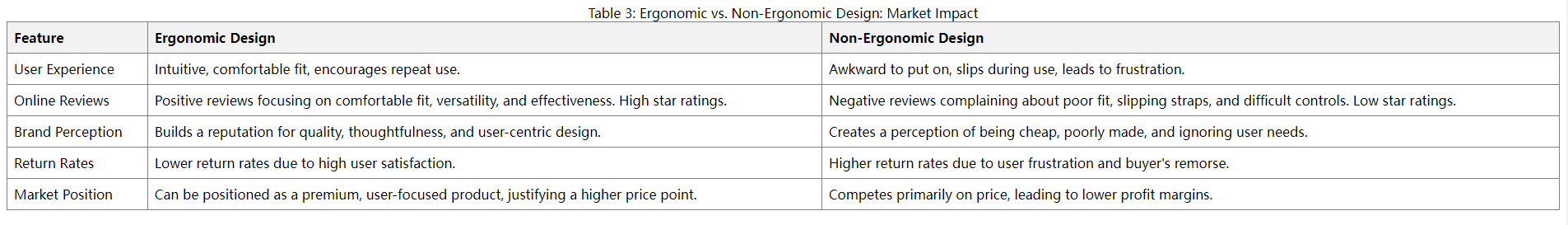

Why do some massagers fly off the shelves while others collect dust? It's not just about power; it is about the total experience. A poor experience leads to bad reviews and low sales.

From my years in this industry, I can confirm that ergonomic design is a primary driver of user experience and market appeal. A comfortable, easy-to-use massager gets used more often, receives better reviews, and builds brand loyalty, which directly translates to higher sales for private label portable massagers.

In a crowded market, technical specifications can start to look very similar from one product to the next. Many massagers offer comparable heat settings, massage modes, and a similar set of features. So, what makes a customer choose one brand over another? The answer is user experience. And the foundation of a great user experience is excellent ergonomic design. It's the silent factor that shapes a user's perception of quality and effectiveness. A product that feels like a natural part of the body, rather than a clumsy appliance, will create a lasting positive impression. This impression is what turns a one-time buyer into a loyal customer and a vocal advocate for your brand. It's the difference between a product that is simply functional and one that is truly desirable.

From First Impression to Long-Term Use

A customer's journey begins the moment they unbox the product. A well-designed, ergonomic massager immediately communicates quality. The fabric feels premium, and the straps are easy to adjust. The controls are intuitive and easy to understand without reading a long manual. This positive first impression is critical. More importantly, good ergonomics encourages continued use. If a device is comfortable to wear and simple to operate, the user is more likely to incorporate it into their daily routine. This frequent use leads to them experiencing the actual therapeutic benefits of the massage, which reinforces their satisfaction with the purchase. In contrast, a device that constantly slips, has scratchy straps, or is confusing to operate often ends up in a drawer, leading to buyer's remorse.

The Direct Impact on Sales and Reviews

In the age of e-commerce, online reviews are everything. Potential customers rely on the experiences of others to make purchasing decisions. Ergonomics plays a huge role in the content of these reviews. A poorly designed massager will generate reviews complaining that it "doesn't stay in place," the "straps are uncomfortable," or the "controls are hard to reach." These negative comments can kill a product's sales momentum. On the other hand, an ergonomically sound product will receive praise for its "perfect, snug fit," "amazing versatility for my knees and arms," and "so comfortable to use." These positive testimonials act as powerful social proof, directly driving sales and improving the product's ranking on e-commerce platforms. Good design doesn't just feel better; it sells better.

Are there specific ergonomic design certifications for portable massagers from Chinese suppliers?

Need to verify a supplier's claims? Anyone can say their product is "ergonomic." Certifications and adherence to standards provide objective proof of a manufacturer's commitment to quality.

While there isn't one single "ergonomic massager" certification, I ensure our products comply with broad international standards like CE, FCC, and RoHS. These cover safety and material quality, which are foundational to ergonomics. We also adhere to ISO 9001 guidelines for quality management in our design process.

This is a very important question, and the answer requires a bit of nuance. Unlike certifications for electrical safety (like CE) or material content (like RoHS), there isn't a single, universally recognized "Certificate of Ergonomics" for consumer products like portable massagers. The term "ergonomic" is often used in marketing, but its true meaning lies in the design process and adherence to established principles, not necessarily in a final stamp of approval. However, a reputable manufacturer can demonstrate their commitment to ergonomics through their compliance with other relevant international standards and their internal quality management systems. These certifications, while not explicitly for ergonomics, are strong indicators of a supplier who takes design, safety, and user well-being seriously.

Relevant International Safety and Material Standards

The foundation of an ergonomic product is that it must be safe to use. This is where key international standards come into play. For products sold in Europe, the CE mark is mandatory. It signifies that the product meets high safety, health, and environmental protection requirements. For the US market, FCC certification is necessary, ensuring the device's electronics don't cause harmful electromagnetic interference. Another critical one is RoHS (Restriction of Hazardous Substances). This directive restricts the use of specific hazardous materials found in electrical and electronic products. For a massager that is in direct contact with the skin, RoHS compliance is crucial for user safety and comfort. A supplier that readily provides these certifications is demonstrating a baseline commitment to quality and user safety, which are core components of an ergonomic philosophy.

Quality Management Systems (ISO 9001)

This is perhaps the most significant indicator of a manufacturer's dedication to a proper design process. ISO 9001 is the international standard for a quality management system (QMS). A factory that is ISO 9001 certified has proven that it has structured, repeatable processes for everything from design and development to production and delivery. A key part of the ISO 9001 standard is the focus on meeting customer requirements and enhancing customer satisfaction. In the context of product development, this means having a formal process for gathering user needs, translating them into design specifications, and validating the final product to ensure it meets those needs. This structured approach, which includes stages for design review and validation (like user testing), is the very essence of how ergonomic products are created. Therefore, a supplier's ISO 9001 certification is a strong sign that they have the framework in place to develop genuinely ergonomic products.

Asking the Right Questions

Since you can't just ask for an "ergonomics certificate," you need to ask more intelligent questions to vet a potential supplier. Instead of asking "Is your product ergonomic?", ask "Can you walk me through your product development process?" or "What kind of user testing did you conduct for this model?" Ask to see their prototyping and user feedback reports. A good ODM partner will be proud to share this information as it demonstrates their expertise. You can also inquire if their designs have won any reputable industrial design awards, such as the iF Design Award or Red Dot Award. These awards programs have stringent criteria that heavily weigh usability, innovation, and, of course, ergonomics. A supplier with such accolades has had their design capabilities validated by a respected third party.

Conclusion

Ergonomic design is crucial for user comfort and market success. At KLCOSY, we blend engineering, rigorous testing, and quality materials to create portable massagers your customers will truly love.