Massager Reliability Testing: A B2B Product Validation Guide

- By Grace

- Updated on

The pre-production "golden sample" you just received is flawless. The design is perfect, the function is smooth, and it feels like a premium product. You sign off, confident in your decision. But here’s the real question, the one that keeps smart sourcing managers up at night: how will this product perform after 500 hours of use, a dozen accidental drops, and three years out in the wild?

The golden sample is a snapshot, not a forecast. A product's true value is in its reliability. I'll never forget what a distributor of high-end wellness products told me. His biggest challenge with a previous supplier was the massive surge in warranty claims after the first year. "The samples were always perfect," he said, "but they couldn't withstand real life." At KLCOSY, we bridge this gap with a rigorous Product Validation Testing (PVT) program, designed to simulate years of use and abuse, giving you verifiable data on massager product lifespan before you commit to a mass order.

This guide will take you inside our reliability lab. I'll break down the specific stress tests your product will undergo and show you how we provide the objective data you need to be confident not just in the sample, but in every single unit of every order.

So, How Can You Predict Performance a Year From Now?

You’re building a brand on the promise of quality, but a high failure rate a year after launch can destroy customer trust and your bottom line. How do you look past the perfect sample and see the product's future weak points?

You have to stress-test it. You subject the product to a battery of accelerated life testing for electronics and massager durability testing that simulate long-term, real-world use. An online retailer who specializes in durable goods told me, "We can't afford the negative reviews from products that don't last. The detailed reliability reports from KLCOSY, including the button cycle test data, are now a mandatory part of our sourcing process."

A golden sample hasn't endured the temperature swings of a delivery truck or the inevitable bumps and drops of daily life. Relying on it to predict long-term performance is like judging a marathon runner by how they look at the starting line. True reliability is proven under pressure. Our PVT program is designed to systematically find and eliminate points of failure before your product ever reaches the production line. We don't just hope it's durable; we prove it with data.

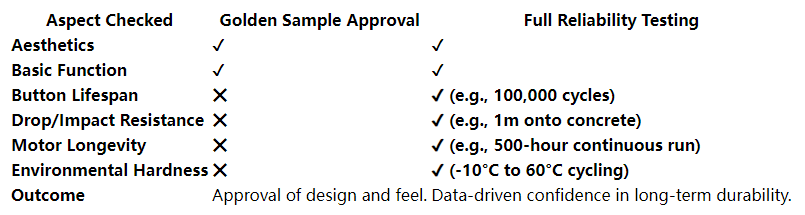

Golden Sample vs. Full Reliability Testing

What Specific Tests Prove a Product is Built to Last?

The head of a chain of physical therapy clinics told us they chose our massagers because the detailed drop-test videos and motor life reports gave them confidence that the devices could withstand the constant, demanding use of a professional clinical setting. That’s what this is all about.

Your customers won't just use the product; they will misuse it. They'll drop it, mash the buttons, and use it in hot or humid environments. So how do we ensure the product is robust enough to survive? We simulate those worst-case scenarios in our lab. This is a key part of our massager supplier quality verification. Our goal is to find the breaking point here, so your customers never find it in their homes.

1. Mechanical Stress & Durability Testing

This is where we simulate physical wear and tear.

- Button/Switch Life Test: We use an automated rig to press each button up to 100,000 times to ensure it won't fail or stick.

- Drop Test: We drop the product from various heights (typically 1 meter) and angles onto a hard surface to simulate accidental falls.

- Vibration Test: The product is subjected to prolonged vibration to simulate the stress of shipping and transportation.

2. Electrical & Performance Life Testing

Here, we focus on the heart of the product—its motor and electronics.

- Accelerated Motor Life Test: We run the motor continuously under load for hundreds of hours (e.g., 500 hours) to simulate years of regular use.

- Battery Cycle Test: The battery is charged and discharged hundreds of times to measure capacity fade and ensure long-term performance.

- Burn-In Test: A sample batch is run continuously for 48-72 hours to catch any "infant mortality" failures in the electronic components.

3. Environmental Hardness Testing

This ensures the product can survive in different climates and conditions.

- Thermal Cycling: The product is placed in a chamber and cycled between extreme hot and cold temperatures (e.g., -10°C to 60°C).

- Humidity Test: The device is tested in a high-humidity environment to ensure moisture does not affect its performance over time.

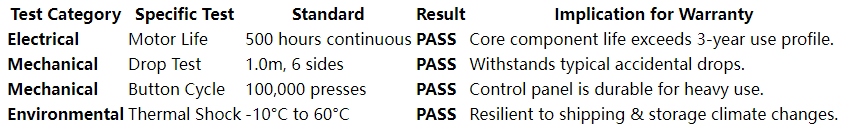

So, How Does This Data Translate into a Reliable Warranty?

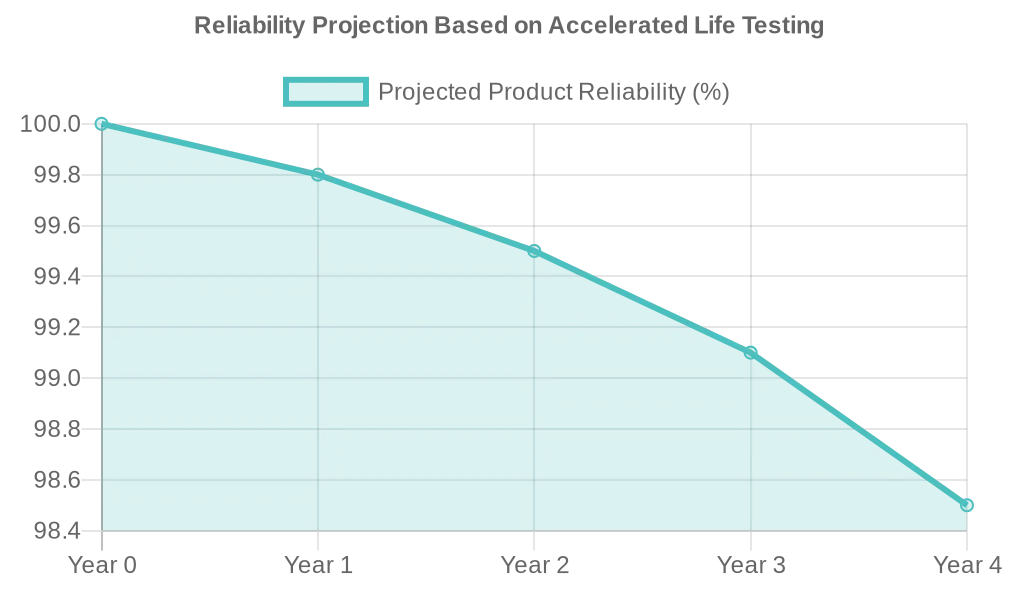

A warranty is only as good as the data that backs it up. You can't confidently offer a 3-year warranty without verifiable proof that the product is engineered to last that long. That's why our warranty isn't a marketing promise; it's a direct reflection of our test results. The calculated Mean Time Between Failures (MTBF) from our lab data gives us a statistically valid prediction of reliability, allowing us to offer a warranty with complete confidence.

The results of our PVT program answer the critical question: what is mean time between failures (MTBF) in massagers? It's a data-driven projection of the product's reliability curve over time. By ensuring the projected MTBF is significantly longer than the warranty period, we build in a substantial safety margin for you and your customers. A retailer who white-labels our products put it best: "Being able to confidently offer a 3-year warranty, backed by KLCOSY's reliability data, has become our single biggest competitive advantage."

Sample Reliability Test Summary (Model: Lumbar Massager KL-88)

The quality of a golden sample is temporary; the data from massager reliability testing is permanent. Our exhaustive Product Validation Testing program is designed to replace uncertainty with evidence, de-risking your investment and protecting your brand's reputation for the long term. A manufacturing partner's commitment to proving product lifespan is the ultimate form of quality assurance. We invite you to request the complete PVT report for your product model and see the data for yourself.