Firmware Development for Smart Massagers: A Guide to De-Risking B2B Manufacturing

- By Grace

- Updated on

You’ve done it. You perfected the ergonomics, picked the best materials, and signed off on a beautiful hardware design. But let's be honest, in the modern smart massager manufacturing landscape, that's only half the battle. The invisible element—the firmware—is what actually brings your product to life. It’s also where the single greatest risk lives: a software bug that could turn thousands of your products into useless "bricked" paperweights.

As the Head of Product Marketing, I’ve seen firsthand how undisciplined firmware development can completely derail a product launch and shatter a brand's reputation. That's why at KLCOSY, we don't treat firmware as an afterthought. It's a core piece of our firmware development services, managed by a rigorous Software Development Lifecycle (SDLC) that’s built from the ground up to give our OEM partners predictability, quality, and security.

So, we're pulling back the curtain on this critical process. We'll show you how we use version control to guarantee every unit is identical, how we systematically squash bugs long before production, and how we protect your intellectual property. The goal? To make sure your smart product is a reliable, future-proof asset for your brand.

The Nightmare Scenario: How to Prevent Firmware Bricking in Manufacturing

A client came to us after their previous supplier made a critical error: they accidentally flashed an old, buggy firmware version onto 5,000 units. The Bluetooth function was unstable, a massive recall was required, and a huge amount of money was lost. They learned the hard way that without a "single source of truth," OEM electronics manufacturing is a high-stakes gamble.

So how do you know for certain that as 10,000 units roll off the line, every single one is being flashed with the correct, final, approved version of the firmware?

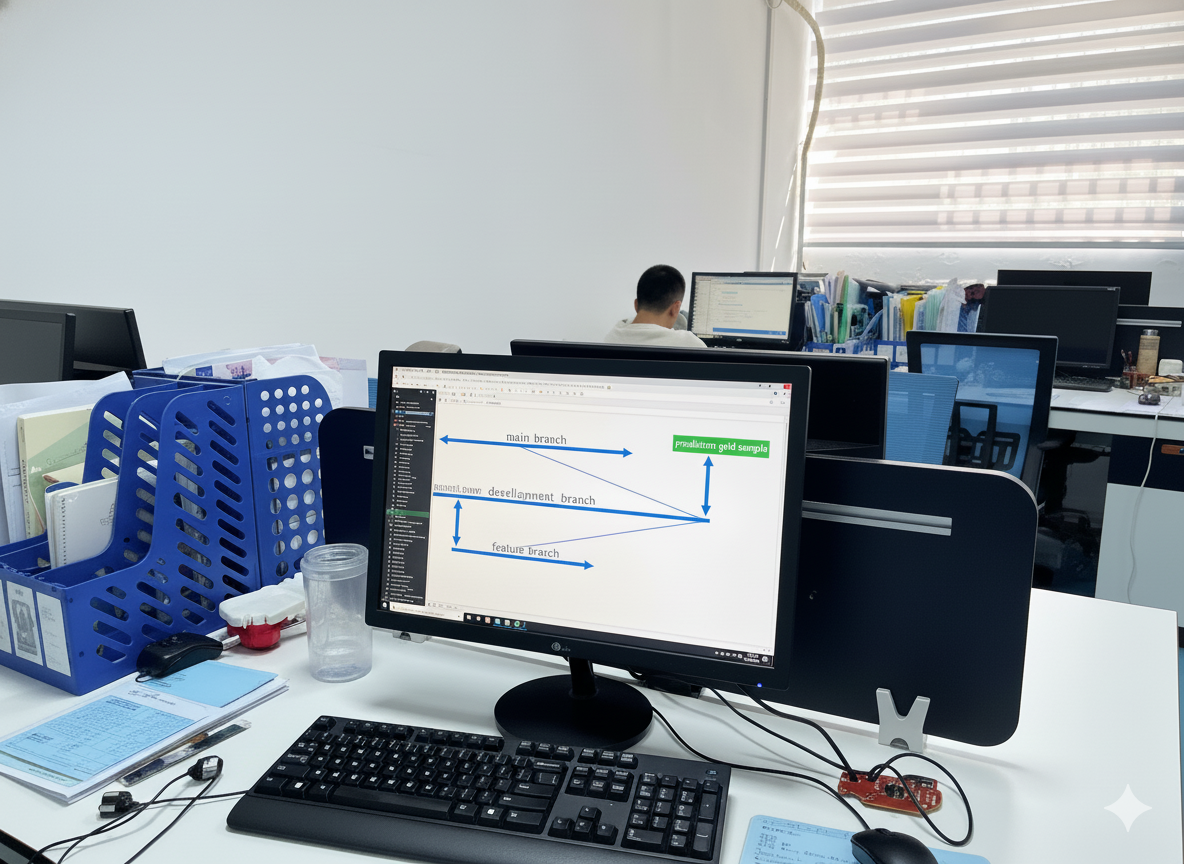

The answer is a powerful system called Git Version Control. Think of Git as a meticulous, unchangeable history book for code. Every single change, revision, and approval is tracked and logged. At KLCOSY, our entire firmware development lives in a secure Git repository, and our process is built on one simple, unbreakable rule: the factory floor can only access the "master" branch. This branch is locked down. It can only be updated by a senior engineer after a new version has passed all of its testing and—most importantly—been formally signed off on by you. This creates a firewall between development, testing, and production, eliminating the risk of human error.

The "Master Branch" is Your Golden Sample

The "master" branch is the single, undisputed source of truth for your product's software. It’s the digital equivalent of a "golden sample" for hardware. Before we start mass production, our flashing tools are hardcoded to pull firmware *only* from this approved branch. This makes it physically impossible for a worker to accidentally select a file from a "test_version" or "dev_build" folder. It guarantees every unit has the exact same, correct, and fully-vetted software, transforming a potential point of catastrophic failure into a repeatable and reliable manufacturing step.

Finding and Fixing Bugs Before They're Your Problem

Your customers expect a seamless experience. The last thing you want are calls about the massager freezing, the app failing to connect, or a massage pattern feeling "off." So how do you find these problems before they do?

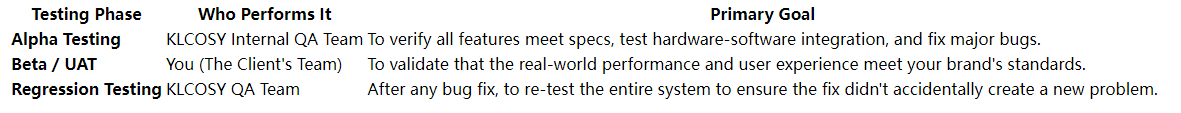

A reliable product is the result of a relentless, systematic hunt for bugs, a true cornerstone of B2B smart wellness device development. Our Quality Assurance (QA) process isn’t a single step; it’s a series of filters designed to catch issues early, when they're cheapest and easiest to fix. And the final, most important filter is you.

We saw this in action with a corporate wellness client. During their final testing phase, they noticed a specific massage pattern's timing felt slightly different from the app's description. It was a minor detail, but it mattered. That invaluable feedback allowed us to make a quick adjustment and perfect the user experience *before* the final release.

Our Collaborative Testing Protocol: You're the Final Check

We designed our process to be completely transparent and collaborative. No firmware is ever finalized for production without your explicit, hands-on approval.

During the UAT phase, we ship you a batch of production-intent units. You get to test them in your own environment, with your own phones, exactly like a customer would. Any feedback is logged in a shared system, tackled by our engineers, and rolled into a new version for you to verify. This feedback loop continues until you're 100% satisfied and give the final "green light."

Your Product's Journey Doesn't End at Launch

What happens six months down the road when a customer finds a minor bug? Or when you get a brilliant idea for a new feature based on user feedback? Is your product frozen in time? And who actually owns the code?

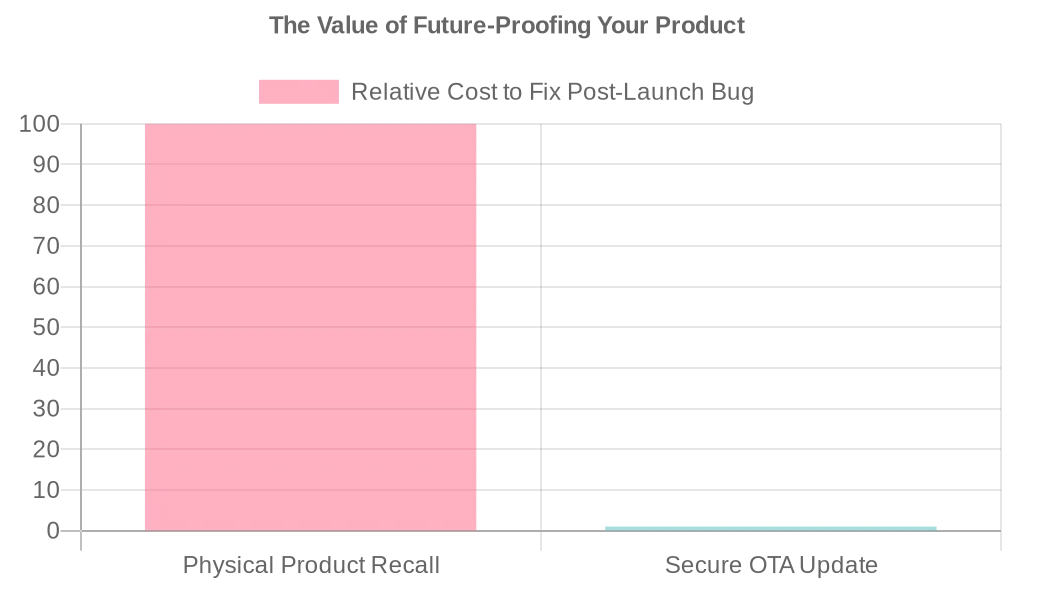

Bottom line: your product can and should evolve. It’s possible through secure OTA updates, and yes, the custom firmware we build for you is your intellectual property. As a leading percussive therapy device ODM, we worked with a fitness tech brand that used an OTA update to add a popular new recovery pattern a year after launch. It delighted their existing customers, boosted reviews, and gave them a fresh marketing angle—all without producing new hardware.

We build all our smart products with secure Over-the-Air (OTA) update capability from day one. It’s your insurance policy and your tool for extending the product's value. If a bug is found post-launch, we can develop a patch, test it, and deploy it securely through the companion app. This turns a potential recall crisis into a manageable software update and allows you to keep your product competitive long after it ships.

Your Intellectual Property is Yours. Period.

Just like you own the physical mold, you own the code. Our OEM development agreement makes this crystal clear. While we might use our own foundational libraries (the "scaffolding"), the unique firmware that defines your product's features and user experience is a work-for-hire that belongs to you. At the end of the project, we securely transfer the full source code and all documentation. This principle of clear ownership is key to intellectual property protection in electronics and gives you ultimate long-term control of your brand's assets.

Conclusion

In a smart product, the hardware is the body, but the firmware is the soul. So when you're finding a reliable smart product supplier, it's crucial to ask the tough questions about their software discipline. Our transparent, collaborative process is designed to de-risk this critical part of smart massager manufacturing. With rigorous version control, a robust testing protocol where you have the final say, and a clear IP ownership policy, we provide the framework you need to launch with confidence, knowing your device is reliable, secure, and built for the future.